Featured

Featured

-

Wholesale China Stainless Steel Filter Basket Exporters Companies – Cost Effective Filter Basket Material – Chongguan

Stainless steel mesh filter basket 1.Material: Stainless steel mesh, steel mesh, copper mesh, black wire mesh etc 2.Mesh count: 2-3200mesh 3.Wire diameter: 0.018-2.5mm 4.Size: 10mm-300mm 5.Shapes: Round shape, rectangular shape, toroidal shape, square shape, oval shape, other special shape 6.Layer: Single layer, multi-layers Perforated metal filter basket 1.Material: Stainless Steel,cast iron,carbon steel,etc. 2.Type: Standard filter basket and slanted filter basket. 3.Filer media: perforatio... -

Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China Stainless Steel Wire Cloth Manufacturers Suppliers – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Twin Loop Wire Binding Quotes Pricelist – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Welded Mesh Security Fencing Factories Pricelist – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ... -

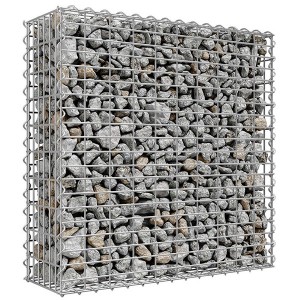

Wholesale China Welded Wire Mesh Rolls Manufacturers Suppliers – Welded Wire Mesh Gabion Box – Chongguan

Welded Mesh Gabion Boxes Sizes: Nominal Box sizes (m) No. of diaphragms (no.) Capacity per box (m3) Standard mesh sizes (mm) Standard wire diameter (mm) 1.0×1.0×0.5 Nil 0.50 50 x 50 75 x 75 100 x 50 100 x 100 Heavily Galvanised or Aluzinc coated wire 2.20, 2.50, 2.70, 3.00 4.00, 5.00 OR Polymer coated on Heavily Galvanised or Aluzinc coated wire 2.5/2.8, 2.7/3.0, 3.0/3.3, 4.0/4.3, 5.0/5.3 1.0×1.0×1.0 Nil 1.00 1.5×1.0×0.5 Nil 0.75 1.5×1.0×1.0 ... -

Wholesale China Binding Wire Online Company Products – High Performance Stainless Steel Wire – Chongguan

1.Stainless steel lock wire – suitable for use in the automotive, aerospace and aeronautics industries and applications. 2.Stainless steel wire for crafts and hardware – suitable for using in jewelry, sculptures, welding, musical instruments and general hardware items such as screws, nails, rivets, key rings, staples, pins, carabiners and more. 3.Stainless steel wire for medical applications – this wire is used in orthodontics, acupuncture needles, microbiology, ophthalmology, surgery and eve... -

Wholesale China Stainless Steel Wire Cloth Factory Quotes – High Performance Stainless Steel Wire – Chongguan

1.Stainless steel lock wire – suitable for use in the automotive, aerospace and aeronautics industries and applications. 2.Stainless steel wire for crafts and hardware – suitable for using in jewelry, sculptures, welding, musical instruments and general hardware items such as screws, nails, rivets, key rings, staples, pins, carabiners and more. 3.Stainless steel wire for medical applications – this wire is used in orthodontics, acupuncture needles, microbiology, ophthalmology, surgery and eve... -

Wholesale China Disc Water Filter Factories Pricelist – Various Shapes of Filter Disc – Chongguan

Filter disc is a type of filter element that is commonly made of stainless steel wire mesh. It has various filtration applications, widely used in the chemical industry, pharmaceutical industry, food industry and other industries. This type filter element is characterized by high filtration precision, good corrosion resistance and good wear resistance. Filter discs have good long term performance. It can be repeatedly washed and used. Our filter disc is available in different weave types, mes... -

Wholesale China Metal Pool Fence Factory Quotes – Bouble Wire Fence for Landscaping – Chongguan

The special specifications are available on request. Double Wire Fence Height × Width Panel mm Mesh Size mm Wire Diameter Post of Height mm Wire Dia mm Wire Dia mm Wire Dia mm 630×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1100 830×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1300 1030×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1500 1230×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1700 1430×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1900 ... -

Wholesale China Welded Mesh Fence Company Products – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

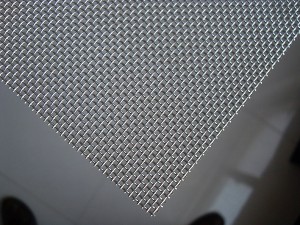

Wholesale China Crimped Wire Mesh Exporters Companies – Stainless Steel Woven Wire Mesh Netting CLoth – Chongguan

Material: SS 201, SS304, SS304L, SS316, SS316L, SS321, SS347,SS430, Monel. Type 304 Often referred to as “18-8″ (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding c...