Featured

Featured

-

Wholesale China Binding Wire Types Manufacturers Suppliers – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

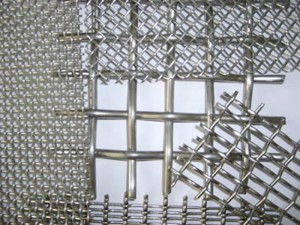

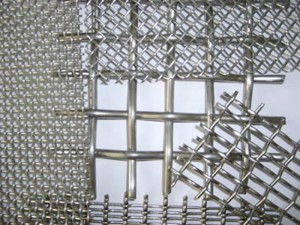

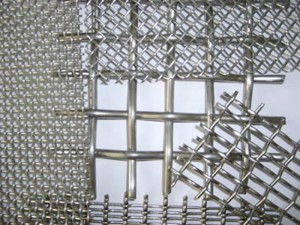

Wholesale China G I Wire Mesh Factories Pricelist – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

Wholesale China Knitted Wire Mesh Factories Pricelist – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

Wholesale China Child Safety Pool Fence Quotes Pricelist – Barbed Wire For Fencing System – Chongguan

Barbed Wire Specification Type Wire Gauge (BWG) Barb distance (cm) Barb length (cm) Electric GalvanizedBarbed wire ; Hot-dip Galvanized Barbed Wire 10# x12# 7.5-15 1.5-3 12# x12# 12# x14# 14# x 14# 14# x16# 16# x16# 16# x18# Pvc Coated Barbed Wire Before coating after coating 1.0mm-3.5mm 1.4mm-4.0mm BWG11#-20# BWG8#-17# SWG11#-20# SWG8#-17# PVC coating thickness: 0.4mm-1.0mmDifferent colors or length are available as customers` request Gauge of Approx... -

Wholesale China Galvanized Wire Mesh Rolls Exporters Companies – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

Wholesale China Welded Wire Mesh Panels Quotes Pricelist – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ... -

Wholesale China Black Wire Mesh Panels Quotes Pricelist – Galvanized Square Wire Mesh for Screening – Chongguan

Low carbon steel wire mesh is the most common plain steel alloy used in manufacturing industrial wire cloth screens due to its tensile strength and high impact resistance. Primarily comprised of iron, low carbon grades is q195. Low abrasion resistance and low corrosion resistance may limit usage in certain applications, however a wide variety of special protective coatings may be applied to improve resistance. Galvanizing (before or after) is the most economical way to protect against corrosi... -

Wholesale China Perforated Filter Tube Manufacturers Suppliers – Sintered Mesh of High Filter Efficiency – Chongguan

Raw Material: SS 316L, SS 304 Filter Rating Range: 0.5 Micron ~ 2000 Microns Filter Efficiency: > 99.99 % Number of Layers: 2 Layers ~ 20 Layers Operation Temperature: ≤ 816 ℃ Length: ≤ 1200 mm Width: ≤ 1000 mm Regular Size (Length*Width): 500 mm*500 mm,1000 mm*500 mm,1000 mm*1000 mm,1200 mm*1000 mm Thickness: 0.5 mm,1 mm,1.5 mm,2 mm,3 mm,5 mm or others 5-Layer Sintered Wire Mesh Sintering is a process that improves the characteristics of woven wire mesh by bonding the contact points of al... -

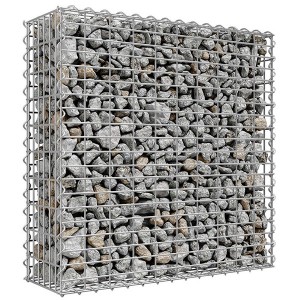

Wholesale China Welded Mesh Manufacturers Manufacturers Suppliers – Welded Wire Mesh Gabion Box – Chongguan

Welded Mesh Gabion Boxes Sizes: Nominal Box sizes (m) No. of diaphragms (no.) Capacity per box (m3) Standard mesh sizes (mm) Standard wire diameter (mm) 1.0×1.0×0.5 Nil 0.50 50 x 50 75 x 75 100 x 50 100 x 100 Heavily Galvanised or Aluzinc coated wire 2.20, 2.50, 2.70, 3.00 4.00, 5.00 OR Polymer coated on Heavily Galvanised or Aluzinc coated wire 2.5/2.8, 2.7/3.0, 3.0/3.3, 4.0/4.3, 5.0/5.3 1.0×1.0×1.0 Nil 1.00 1.5×1.0×0.5 Nil 0.75 1.5×1.0×1.0 ... -

Wholesale China Hydraulic Strainer Filter Company Products – Sintered Mesh of High Filter Efficiency – Chongguan

Raw Material: SS 316L, SS 304 Filter Rating Range: 0.5 Micron ~ 2000 Microns Filter Efficiency: > 99.99 % Number of Layers: 2 Layers ~ 20 Layers Operation Temperature: ≤ 816 ℃ Length: ≤ 1200 mm Width: ≤ 1000 mm Regular Size (Length*Width): 500 mm*500 mm,1000 mm*500 mm,1000 mm*1000 mm,1200 mm*1000 mm Thickness: 0.5 mm,1 mm,1.5 mm,2 mm,3 mm,5 mm or others 5-Layer Sintered Wire Mesh Sintering is a process that improves the characteristics of woven wire mesh by bonding the contact points of al... -

Wholesale China Hog Wire Trellis Company Products – High Performance Stainless Steel Wire – Chongguan

1.Stainless steel lock wire – suitable for use in the automotive, aerospace and aeronautics industries and applications. 2.Stainless steel wire for crafts and hardware – suitable for using in jewelry, sculptures, welding, musical instruments and general hardware items such as screws, nails, rivets, key rings, staples, pins, carabiners and more. 3.Stainless steel wire for medical applications – this wire is used in orthodontics, acupuncture needles, microbiology, ophthalmology, surgery and eve... -

Wholesale China Galvanized Welded Wire Mesh Manufacturers Suppliers – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r...