Featured

Featured

-

Wholesale China Welded Mesh And Backfill Mesh Factories Pricelist – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ... -

Wholesale China Cut Wire Factories Pricelist – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Wire Fencing Materials Quotes Pricelist – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Galvanized Welded Wire Company Products – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Chain Link Fence Tension Wire Factory Quotes – Razor Barbed Wire For Security Fence – Chongguan

Razor Blade Type and Specification Reference number Thickness/mm Wire Dia/mm Barb length/mm Barb width/mm Barb spacing/mm BTO-10 0.5±0.05 2.5±0.1 10±1 13±1 26±1 BTO-12 0.5±0.05 2.5±0.1 12±1 15±1 26±1 BTO-18 0.5±0.05 2.5±0.1 18±1 15±1 33±1 BTO-22 0.5±0.05 2.5±0.1 22±1 15±1 34±1 BTO-28 0.5±0.05 2.5 28 15 45±1 BTO-30 0.5±0.05 2.5 30 18 45±1 CBT-60 0.5±0.05 2.5±0.1 60±2 32±1 100±2 CBT-65 0.5±0.05 2.5±0.1 65±2 21±1 100±2 Outer diameter No. of loops Standard len... -

Wholesale China Sintered Filter Disc Quotes Pricelist – Sintered Mesh of High Filter Efficiency – Chongguan

Raw Material: SS 316L, SS 304 Filter Rating Range: 0.5 Micron ~ 2000 Microns Filter Efficiency: > 99.99 % Number of Layers: 2 Layers ~ 20 Layers Operation Temperature: ≤ 816 ℃ Length: ≤ 1200 mm Width: ≤ 1000 mm Regular Size (Length*Width): 500 mm*500 mm,1000 mm*500 mm,1000 mm*1000 mm,1200 mm*1000 mm Thickness: 0.5 mm,1 mm,1.5 mm,2 mm,3 mm,5 mm or others 5-Layer Sintered Wire Mesh Sintering is a process that improves the characteristics of woven wire mesh by bonding the contact points of al... -

Wholesale China Stainless Steel Wire Fence Quotes Pricelist – Bouble Wire Fence for Landscaping – Chongguan

The special specifications are available on request. Double Wire Fence Height × Width Panel mm Mesh Size mm Wire Diameter Post of Height mm Wire Dia mm Wire Dia mm Wire Dia mm 630×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1100 830×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1300 1030×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1500 1230×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1700 1430×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1900 ... -

Wholesale China Twisted Ties Wire Manufacturers Suppliers – Anti-corrosion PVC Coated Metal Wire – Chongguan

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires ( annealed wire, galvanized wire, stainless steel wire, Galfan wires, etc). The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics. Materials before PVC coating: steel wire, galvanized wire, redrawing wire, annealed wire, etc. Surface: plastic covering or plastic coat... -

Wholesale China Wire Reinforcing Mesh Factory Quotes – UV Stabilized Plastic Insect Screen – Chongguan

Economical. The plastic insect screen is much cheaper than other material insect screen. Environmental friendly. All of the materials are recycled, it will not harm to the environments and people. Pure material. Our materials are all pure material, not the reborn plastic. UV stabilized. The material can resist the UV rays. Air movement. The square mesh of the insect screen permit the good movement of the air and water. The plastic insect screen can be used in the windows, doors, porches and p... -

Wholesale China Binding Wire Suppliers Company Products – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China Steel Wire Mesh Panels Factories Pricelist – Most Durable Aluminium Window Screen – Chongguan

Aluminum window screen is made of Al-Mg alloy wire in plain weaving. Screens made from aluminum mesh is one of the sturdiest and most durable screens available. They have a long lifespan and will protect you from different weather conditions, including rain, strong winds, and even hail in some cases. Aluminum mesh screens are resistant to abrasion, corrosion, and rust, making them a great screen choice for nearly any environment. Aluminum wire window screens also will not sag or rust, extend... -

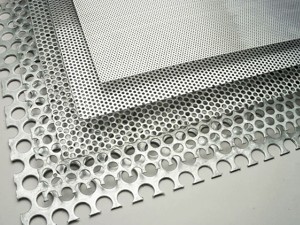

Wholesale China Stainless Steel Woven Mesh Factory Quotes – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can...