Featured

Featured

-

Wholesale China Welded Mesh Bird Cage Quotes Pricelist – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Black Wire Mesh Factory Quotes – Galvanized Square Wire Mesh for Screening – Chongguan

Low carbon steel wire mesh is the most common plain steel alloy used in manufacturing industrial wire cloth screens due to its tensile strength and high impact resistance. Primarily comprised of iron, low carbon grades is q195. Low abrasion resistance and low corrosion resistance may limit usage in certain applications, however a wide variety of special protective coatings may be applied to improve resistance. Galvanizing (before or after) is the most economical way to protect against corrosi... -

Wholesale China Pvc Coated Wire Mesh For Cages Factory Quotes – Galvanized Square Wire Mesh for Screening – Chongguan

Low carbon steel wire mesh is the most common plain steel alloy used in manufacturing industrial wire cloth screens due to its tensile strength and high impact resistance. Primarily comprised of iron, low carbon grades is q195. Low abrasion resistance and low corrosion resistance may limit usage in certain applications, however a wide variety of special protective coatings may be applied to improve resistance. Galvanizing (before or after) is the most economical way to protect against corrosi... -

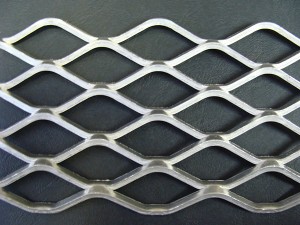

Wholesale China Stainless Steel Security Mesh Exporters Companies – Stronger Expanded Metal Mesh Sheet – Chongguan

Made by slitting and stretching metal sheets to create diamond-shaped openings, Expanded Metal forms screens, window security panels and machine guards to name a few applications for this practical and versatile product line. In the decorative version of the product, shelving, signage, and ceiling tiles are among the most popular applications. Expanded Metal is supplied in a Standard (Raised) diamond pattern or a Flattened diamond pattern. Grating and Catwalk Expanded Metals are also part of ... -

Wholesale China Welded Steel Wire Mesh Factories Pricelist – Stainless Steel Welded Wire Mesh – Chongguan

All the spacing between wires are controlled by an automatic mechanism of high reliability. So the welded wire mesh size like wire diameters, opening size and panel weight are all available in a wide range. According to its size it can be made into panels and rolls. The materials and size can be chosen from a wide range. Materials: SS201, SS202, SS302, SS304, SS304L, SS316, SS316 and so on. Wire diameter: from 0.6 mm to 2.6 mm. Mesh opening: mini 6.4 mm and max 200 mm is available. Panels: 3 ... -

Wholesale China Book Binding Wire Factories Pricelist – High Performance Stainless Steel Wire – Chongguan

1.Stainless steel lock wire – suitable for use in the automotive, aerospace and aeronautics industries and applications. 2.Stainless steel wire for crafts and hardware – suitable for using in jewelry, sculptures, welding, musical instruments and general hardware items such as screws, nails, rivets, key rings, staples, pins, carabiners and more. 3.Stainless steel wire for medical applications – this wire is used in orthodontics, acupuncture needles, microbiology, ophthalmology, surgery and eve... -

Wholesale China Stainless Steel Mesh Sheets Company Products – Steel Grating For Stairs and Walkway – Chongguan

As producing method: 1.Welded steel grating 2.Press-locked grating 3.Swage-locked grating 4.Riveted grating 5.Offshore Platform Reinforced Floor Grating As material: 1.Aluminum grating 2.Stainless steel grating 3.Expanded Steel Grating 4.Fiberglass grating No. Item Description 1 Bearing Bar Size 25×3, 25×4, 25×4.5, 25×5, 30×3, 30×4, 30×4.5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10—100x10mm etc. I bar: 25x5x3... -

Wholesale China Wire Mesh Manufacturers Factory Quotes – UV Stabilized Plastic Insect Screen – Chongguan

Economical. The plastic insect screen is much cheaper than other material insect screen. Environmental friendly. All of the materials are recycled, it will not harm to the environments and people. Pure material. Our materials are all pure material, not the reborn plastic. UV stabilized. The material can resist the UV rays. Air movement. The square mesh of the insect screen permit the good movement of the air and water. The plastic insect screen can be used in the windows, doors, porches and p... -

Wholesale China Best Garden Fence Company Products – High Security 358 Mesh Fence – Chongguan

Panels Post Fence Panel Size Post Size Post Height Total Number of Fixings Height Height/Width Length/Width/Thickness Inters- 1 clamp Corners-2 clamp m mm mm mm 2.0 2007 × 2515 60×60×2.5mm 2700 7 14 2.4 2400 × 2515 60×60×2.5mm 3100 9 18 3.0 2997 × 2515 80×80×2.5mm 3800 11 22 3.3 3302 × 2515 80×80×2.5mm 4200 12 24 3.6 3607 × 2515 100×60×3mm 4500 13 26 3.6 3607 × 2515 100×1... -

Wholesale China Stainless Wire Fence Quotes Pricelist – Anti-corrosion PVC Coated Metal Wire – Chongguan

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires ( annealed wire, galvanized wire, stainless steel wire, Galfan wires, etc). The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics. Materials before PVC coating: steel wire, galvanized wire, redrawing wire, annealed wire, etc. Surface: plastic covering or plastic coat... -

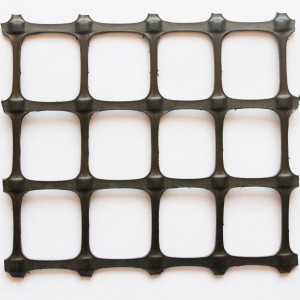

Wholesale China Stainless Steel Woven Mesh Quotes Pricelist – High Strength Biaxial Plastic Geogrid – Chongguan

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine. Index Properties Test Method Unit GG1515 GG2020 GG3030 GG4040 MD TD MD TD MD TD MD TD Polymer – – PP PP PP PP Minimum Carbon Black ASTM D 4218 % 2 2 2 2 Tensile Strength@ 2% Strain ASTM D 6637 Kn/m 5 5 7 7 10.5 10.5 14 14 Tensile Strength@ 5% Strain ASTM D 6637 Kn/m 7 7 14 14 21 21 28 2... -

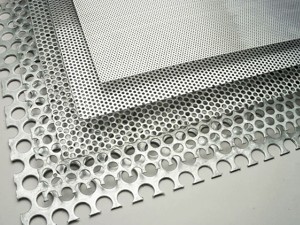

Wholesale China Perforated Stainless Steel Mesh Exporters Companies – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can...