Wholesale China Hydraulic Filter Base Factories Pricelist – Sintered Mesh of High Filter Efficiency – Chongguan

Wholesale China Hydraulic Filter Base Factories Pricelist – Sintered Mesh of High Filter Efficiency – Chongguan Detail:

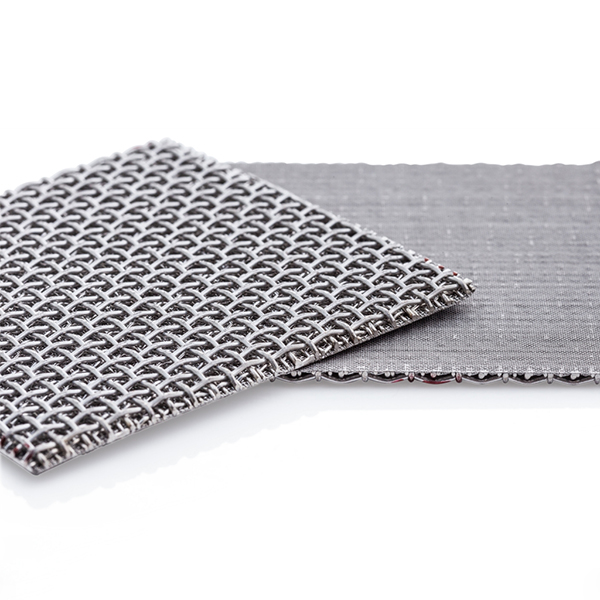

Raw Material: SS 316L, SS 304

Filter Rating Range: 0.5 Micron ~ 2000 Microns

Filter Efficiency: > 99.99 %

Number of Layers: 2 Layers ~ 20 Layers

Operation Temperature: ≤ 816 ℃

Length: ≤ 1200 mm

Width: ≤ 1000 mm

Regular Size (Length*Width): 500 mm*500 mm,1000 mm*500 mm,1000 mm*1000 mm,1200 mm*1000 mm

Thickness: 0.5 mm,1 mm,1.5 mm,2 mm,3 mm,5 mm or others

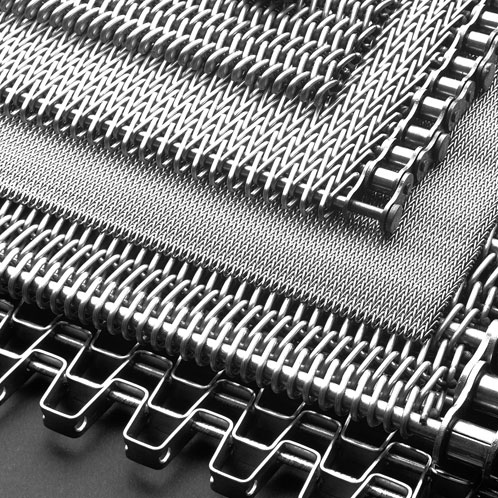

5-Layer Sintered Wire Mesh

Sintering is a process that improves the characteristics of woven wire mesh by bonding the contact points of all the wires together to form a mesh whose wires are securely fused in place. This is achieved through a combination of heat and pressure, and the result is a single layer sintered wire mesh.

Sintered Wire Mesh with Perforated Metal

This type of sintered wire mesh laminate is made by taking several layers of woven wire mesh and sintering them to a layer of perforated metal. The woven wire mesh layers consist of a filter layer, a protective layer, and possibly a buffer layer between the fine mesh layer and the perforated plate. The perforated plate is then added as the base and the entire structure is sintered together to form a very strong yet tractable plate.

Sintered Square Weave Mesh

This type of sintered wire mesh laminate is made by sintering multiple layers of plain weave square woven wire mesh together. Because of the large open area percentages of the square woven wire mesh layers, this type of sintered wire mesh laminate has good permeability characteristics and low resistance to flow. It can be designed with any number and combination of square plain weave wire mesh layers to achieve particular flow and filtration characteristics.

Sintered Dutch Weave Mesh

This type of sintered wire mesh laminate is made by sintering 2 to 3 layers of plain Dutch woven wire mesh together. This type of stainless steel sintered wire mesh laminate has evenly spaced openings and good permeability to flow. It also has very good mechanical strength due to the heavy dutch woven wire mesh layers.

1. Sintered wire mesh is made from multilayer wire cloth

2. Sintered wire mesh is sintered in a high temperature vacuum furnace

3. Sintered wire mesh is surface filtration

4. Sintered wire mesh is good for backwash

5. Sintered wire mesh has uniform pore size distribution

6. High mechanical strength

7. High temperature resistance

8. High filter efficiency

9. High corrosion resistance

10. Washable and Cleanable

11. Reusable

12. Long service life

13. Easy to be welded, fabricated

14. Easy to be cut into different shapes, such as circular, sheet

15. Easy to be made into different style, such as tube style, conical style

Polymers filtration, high temperature liquid filtration, high temperature gases filtration, steam filtration, catalysts filtration, water filtration, beverages filtration.

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for Wholesale China Hydraulic Filter Base Factories Pricelist – Sintered Mesh of High Filter Efficiency – Chongguan , The product will supply to all over the world, such as: Washington, Malta, Juventus, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.